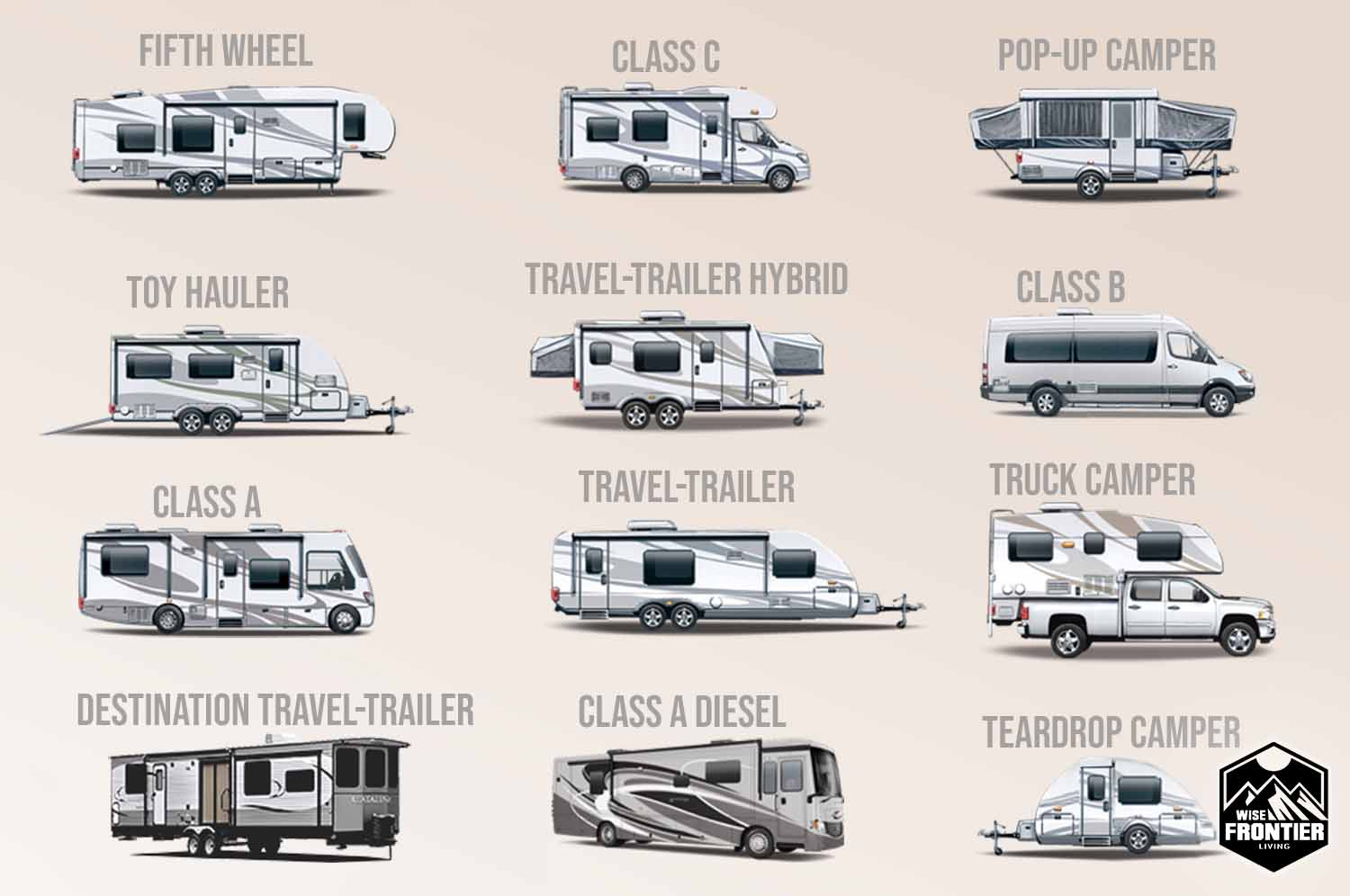

Several types of braking systems are used in camper trailers, including electric trailer brakes and surge brakes.

Electric brakes work through a controller installed in the towing vehicle that applies power to the trailer’s brakes in proportion to the towing vehicle’s deceleration.

Surge brakes, however, are a hydraulic system that activates when the towed vehicle pushes against the towing vehicle during slowing or stopping.

Stopping Power: Understanding Brakes on Camper Trailers

Types of Trailer Brakes and How They Work

When towing a camper trailer, ensuring that you have the right brakes installed is paramount for your safety. Each type of brake system has its specific mechanism and suitability based on the towing vehicle and trailer size. Let’s look at how the common types work.

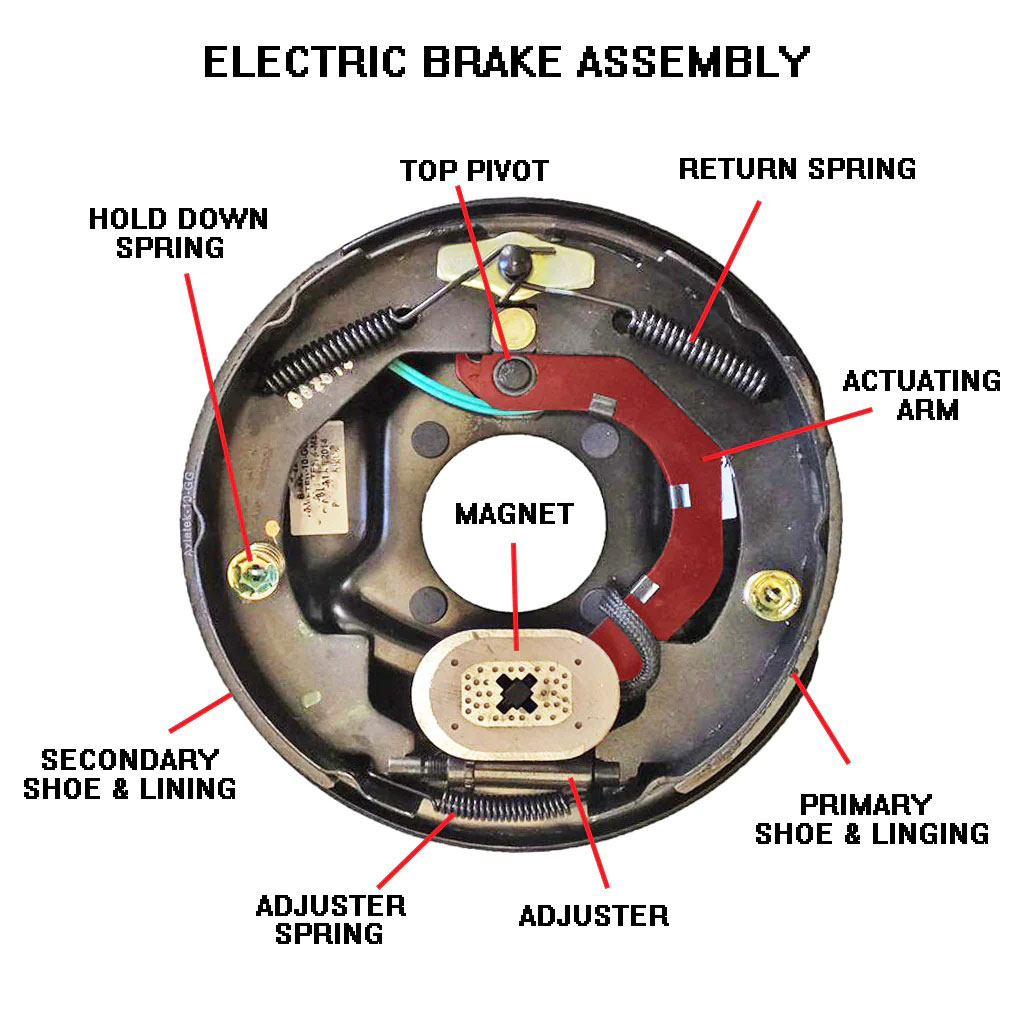

Electric Trailer Brakes

Electric trailer brakes are a popular choice for many trailers because of their simplicity and effectiveness.

When I apply the brakes in my towing vehicle, an electrical signal is sent to the electromagnet in each of the trailer’s wheels.

This magnet then engages the brake drum or disc, providing the necessary friction to slow down the trailer.

It’s vital to have a brake control unit installed in the towing vehicle to modulate the force applied to the trailer’s brakes.

Hydraulic Surge Brakes

Hydraulic surge brakes, also known as hydraulic brakes, activate through a master cylinder located at the coupler of the trailer.

As I decelerate my towing vehicle, the trailer pushes forward against the hitch. This action compresses the hydraulic fluid in the cylinder, which then applies pressure to the trailer’s brake pads or shoes. It is an entirely mechanical process that doesn’t require an electronic brake controller.

Air Brake Systems

Lastly, air brake systems—often used in larger trailers or commercial hauling—rely on stored air pressure to apply force to the brakes.

When you hit the brake pedal, air is released into the brake system to activate it. Some versions also include an air assist feature that supports hydraulic systems for extended stopping power.

In each case, understanding and maintaining these systems are essential to ensure the trailer’s brakes operate reliably and effectively.

Installation and Adjustment of Camper Trailer Brakes

When installing and adjusting camper trailer brakes, precision is crucial. I ensure that electric brakes are properly connected and aligned, focusing on the wiring, the use of adjustment tools, and the critical role of the adjustment wheel.

Installing Electric Brakes

Tools & Materials Needed:

- Electric brake kit

- Wiring harness

- Screwdrivers and pliers

- Socket set

- Jack stands

- Torque wrench

Steps:

- Safety First: I always start by chocking the wheels and lifting the trailer using jack stands to secure it off the ground.

- Mounting Brakes: After removing the wheels, I mount the electric brake assembly to the axle, ensuring it’s firmly in place.

- Wiring: I then carefully connect the brake’s wiring harness to the tow vehicle’s 7-pin connector, paying close attention to ensure all connections are tight and free of corrosion.

Adjusting Brake Systems

Tools & Materials Needed:

- Adjustment tool or flathead screwdriver

- Jack stand

- Flashlight (optional)

Steps:

- Wheels Off: With the trailer securely on the jack stand, I remove the wheels to gain access to the brake assembly.

- Adjustment Wheel Access: I locate the adjustment wheel through the access hole in the backing plate—sometimes a flashlight is handy for this step.

- Turning the Wheel: Using the adjustment tool, I turn the adjustment wheel until there’s slight resistance when spinning the drum, then back off slightly to ensure the wheel spins freely. This step is vital to prevent over-tightening which could cause drag.

By meticulously installing and setting up the brake systems, I ensure safety and reliability in camper trailers. With the right knowledge, the task of maintaining your trailer brakes becomes straightforward and effective.

Maintenance and Inspection for Optimal Performance

Proactive maintenance and regular inspections are key to ensuring the longevity and reliable performance of your camper trailer’s brakes. A thoughtful approach to brake maintenance can prevent costly repairs and dangerous situations on the road.

Routine Brake Maintenance

I always begin with checking the brake fluid levels, as low fluid can be a sign of a potential leak or indicate that the brake pads are worn and need replacing.

Replacing brake pads before they become too thin is essential to avoid damage to the rotors. For drum brakes, regular adjustment ensures that the brakes engage properly when applied. I also make it a habit to check drums for any signs of wear or damage, which could hinder the effective operation of the brakes.

- Monthly: Check brake fluid levels and top up if necessary

- Bi-annually: Inspect brake pads for wear; replace if less than 1/4 inch thick

- Annually: Clean and adjust drum brakes, inspect rotors for grooving or damage, and replace if necessary

Conducting Brake Inspections

A comprehensive inspection is something I take very seriously. It encompasses a thorough assessment of all the components of the brake system.

When inspecting, I focus on the physical condition of brake pads, rotors, and drums, ensuring there are no cracks or excessive wear. I listen for unusual noises while applying the brakes, as this can be an indicator that a brake service is due.

Additionally, if the camper trailer has been in storage or inactive, checking for seized components is crucial. Inspection also involves ensuring proper lubrication of the moving parts; without it, brake efficiency can be severely compromised.

- Visual Check: Pads, rotors, drums for wear and damage

- Auditory Check: Listen for grinding or squealing noises while braking

- Operational Check: Apply brakes at low speeds to ensure smooth and even stopping

Routine maintenance and thorough inspections are my non-negotiable practices for keeping camper trailer brakes in the best shape. Following these protocols helps me and my trailer stay safe on every journey.

Understanding Towing Dynamics and Brake Controllers

When I tow a trailer, understanding how the weight affects momentum and how brake controllers work is vital to ensure my safety and the safety of others.

Towing Capacity and Brake Force

Towing capacity is not just about the weight my vehicle can pull; it’s also about the control and stopping power my brake system can handle.

The weight of the tow vehicle and trailer combined must not exceed the vehicle’s towing capacity. Brake force needs to be sufficient to stop this combined mass.

As the weight increases, the momentum under movement does too, requiring more force to bring the ensemble to a stop. Ensuring that my tow vehicle has ample brake force, including well-maintained brake pads or shoes, is critical to the safety and functionality of my towing setup.

Brake Controllers Explained

Brake controllers are devices that manage the brake force applied to a trailer’s brakes in a gradual and controlled manner — an absolute necessity for safe towing. There are two primary types of brake controllers: proportional controllers and time-delayed controllers.

- Proportional Controllers: These devices detect how quickly I’m stopping my tow vehicle and apply a corresponding amount of brake force to the trailer.

This results in synchronized braking that matches the trailer’s momentum to the vehicle’s deceleration rate. I prefer proportional controllers because they typically offer smoother and more responsive braking. - Time-Delayed Controllers: A preset amount of braking force is sent to the trailer’s brakes after a set delay that I can adjust. Although more cost-effective, they might not provide braking as seamlessly in sync with my tow vehicle as the proportional type.

By using the correct brake controller, I can make sure that the towing experience is as smooth as possible and avoid undue stress on my braking system or compromising on safety.

Enhanced Safety Features for Camper Trailers

When towing camper trailers, my number one priority is safety. Specifically, the integration of advanced brake systems like breakaway systems and supplemental braking systems is crucial. These systems are essential especially when considering the gross vehicle weight rating (GVWR) of your setup, ensuring that you maintain control at all times during your travel.

Breakaway Systems

Breakaway systems are a mandatory safety feature for most towable campers. In the event that my camper becomes uncoupled from the towing vehicle, the breakaway system activates the camper’s brakes, bringing it to a halt.

It’s a simple setup, where a pin is connected to a switch that, once pulled, powers the trailer’s brakes. This system is designed to engage only when separation occurs, providing an immediate response to a potentially dangerous situation.

Supplemental Braking Systems

On top of the standard brake system, I always recommend a supplemental braking system, especially for those campers that approach their maximum GVWR. These systems work in tandem with the towing vehicle’s brakes, reducing wear and improving stopping power.

For instance, auxiliary braking systems can be installed which aid by providing additional braking force proportionate to the towing vehicle’s brake intensity. This not only enhances safety but also ensures compliance with state laws, which often require such systems for heavier trailers.

Leave a Reply